Introducing the Complexities of Fasteners and Machining Procedures for Optimum Efficiency

In the realm of engineering and manufacturing, the choice of fasteners and the details of machining processes play a crucial function in determining the best efficiency and sturdiness of a product. From the relatively uncomplicated task of choosing the best kind of bolt to the complex accuracy machining strategies employed, every action in this process demands careful focus to information. As we begin on this exploration right into the globe of bolts and machining, we will uncover the refined yet critical aspects that can substantially impact the performance and high quality of the final item, clarifying the frequently overlooked elements that can make all the distinction in attaining optimum efficiency.

Value of Appropriate Bolt Selection

Picking the proper fasteners is essential in guaranteeing the architectural stability and long life of any kind of mechanical assembly. Fasteners play an essential function in holding parts with each other firmly, with the appropriate choice contributing significantly to the general performance and integrity of the assembly. When choosing bolts, elements such as product compatibility, ecological conditions, load-bearing capacity, and ease of setup need to be meticulously thought about to assure optimum efficiency.

Improper bolt choice can bring about a series of concerns, consisting of helping to loosen, deterioration, and also structural failing. Using bolts that are not suited to the specific demands of the setting up can endanger its functionality and posture safety and security dangers. As a result, designers and designers need to thoroughly review the application requires and select bolts that satisfy or exceed the necessary criteria and specifications.

Additionally, the appropriate bolt choice process involves examining the joint style, prepared for loads, vibration levels, and possible thermal development or contraction to make certain that the selected fasteners can stand up to the operating problems properly. By focusing on correct fastener selection, producers can enhance the high quality, durability, and performance of their mechanical settings up.

Types and Features of Fasteners

An important element of mechanical settings up exists in recognizing the varied types and special attributes of bolts used in various industrial applications. Bolts are important components that hold frameworks with each other, ensuring stability and performance.

Screws are threaded bolts that are typically used to sign up with 2 or even more elements together. Nuts are internally threaded bolts that mate with screws to hold elements with each other. Washing machines are slim plates that disperse the load of a bolt, protecting against damage to the product being attached.

Comprehending the characteristics of each kind of bolt is important for picking the right one for a specific application, guaranteeing ideal performance and reliability of the mechanical setting up. Fasteners and Machining.

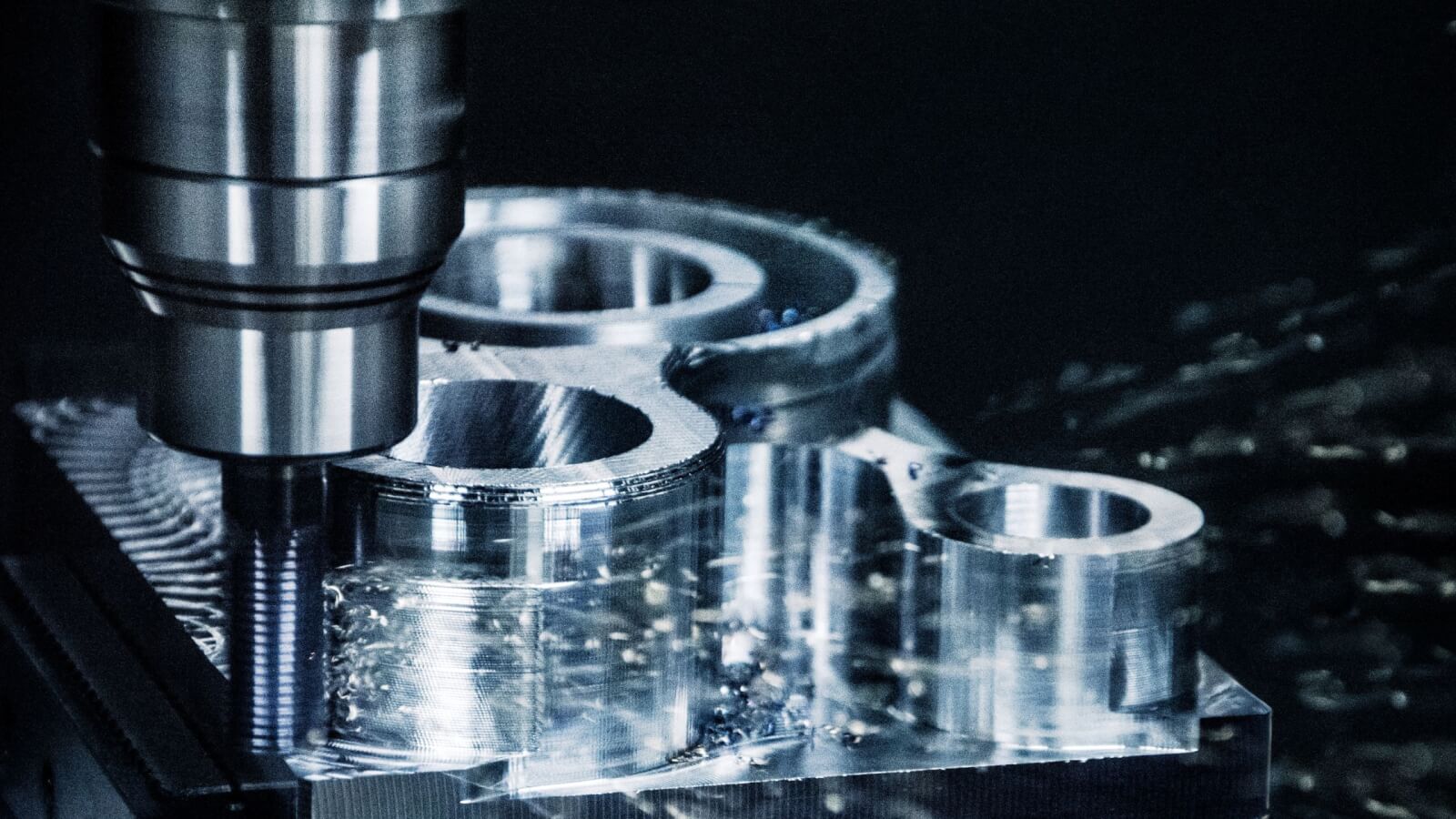

Accuracy Machining Methods for Performance

The elaborate layout needs of numerous bolts demand employing precision machining strategies for optimum performance in producing processes. Accuracy machining is vital in ensuring that fasteners fulfill the exact specs needed for their intended application. Among the main techniques made use of in accuracy machining is Computer Numerical Control (CNC) machining, which makes it possible for high degrees of accuracy and repeatability in the production of fasteners. CNC machines can performing intricate cuts and forming operations with minimal human treatment, causing boosted effectiveness and consistency in the production process.

By making use of precision machining strategies, suppliers can boost the high quality of bolts, reduce product waste, and enhance general manufacturing effectiveness. The use of advanced machining processes helps guarantee that bolts satisfy industry criteria and consumer assumptions for efficiency and dependability.

Variables Affecting Machining Refine Efficiency

Various variables play a substantial duty in determining the performance of machining processes in the production of bolts. The very first critical factor is the selection of reducing devices. Choosing the proper devices based upon the material being machined, preferred finish, and reducing speeds can greatly impact the performance and high quality of the machining procedure. In addition, the cutting parameters such as cutting rate, feed price, and deepness of cut are necessary variables that affect efficiency. Fasteners and Machining. Maximizing these specifications based on the specific needs of the bolt being produced is vital to accomplishing cost-effective and exact machining.

Machine rigidness and click here to find out more stability additionally play a vital duty in establishing machining procedure efficiency. A stable machine with Look At This very little vibrations can improve precision and protect against tool wear, leading to far better general performance. The ability and experience of the maker driver can not be taken too lightly. An experienced operator can make real-time modifications, troubleshoot issues effectively, and guarantee that the machining process runs efficiently, ultimately affecting the last top quality of the bolt.

Quality Assurance Measures in Manufacturing

Factors influencing machining procedure performance, such as reducing device option and machine security, directly impact the execution of quality assurance steps in manufacturing. Quality control procedures are essential in making certain that products fulfill the required requirements and standards. In the production process, numerous strategies are employed to maintain top quality standards. Evaluation and testing play a vital function in recognizing any variances from the preferred result. Normal maintenance of machining tools is likewise crucial to support quality assurance. Calibration of tools and equipments is essential to make sure exact and precise production procedures. Furthermore, implementing standard operating procedures and methods can aid in maintaining uniformity and quality throughout the production line. Quality control measures not only concentrate on the end item but likewise on every stage of the production procedure to stop mistakes and problems. By adhering to stringent quality control procedures, producers can boost customer fulfillment, construct a credibility for dependability, and inevitably accomplish optimal efficiency in their machining procedures.

Final Thought

In conclusion, choosing the right fasteners and making use of precision machining methods are essential for ideal performance in producing processes. Understanding the kinds and characteristics of bolts, together with variables affecting machining process efficiency, can bring about enhanced performance and quality assurance procedures. By taking note of these ins and outs, manufacturers can accomplish higher degrees of efficiency and dependability in their items.

In the world of design and production, the choice of fasteners and the intricacies of machining processes play an essential role in figuring out the best efficiency discover this and resilience of a product (Fasteners and Machining). One of the main strategies utilized in accuracy machining is Computer system Numerical Control (CNC) machining, which allows high degrees of precision and repeatability in the production of bolts. The use of advanced machining processes aids make sure that bolts meet sector standards and consumer assumptions for efficiency and dependability

In conclusion, choosing the appropriate fasteners and making use of precision machining techniques are vital for optimal performance in manufacturing processes. Comprehending the types and attributes of fasteners, along with factors influencing machining process efficiency, can lead to improved performance and high quality control steps.