Rumored Buzz on Premier Aluminum Llc

Table of ContentsLittle Known Facts About Premier Aluminum Llc.Unknown Facts About Premier Aluminum LlcAll About Premier Aluminum LlcGetting My Premier Aluminum Llc To WorkSome Known Details About Premier Aluminum Llc

When selecting an aluminum foundry for your production needs, it's important to study a number of variables. Among one of the most critical elements to take into consideration is the experience and competence of the shop. Picking a factory that has the ideal understanding of the aluminum spreading process, and the profile to show for it, assists to have a successful result for your project.Having the experience and sector knowledge to engineer your castings for optimal manufacturing and quality results will certainly streamline the project. Producing aluminum castings calls for a facility set of processes to accomplish the best results. When selecting a brand-new aluminum factory to companion with, ensure they have considerable sector experience and are educated regarding all aspects of the light weight aluminum spreading procedure: layout, manufacturing, product analysis, and product screening.

The factory needs to also have a proven performance history of supplying remarkable items that fulfill or go beyond consumer expectations. Quality assurance should also be at the top of your checklist when selecting an aluminum foundry. By dealing with a qualified shop who adheres to the standards for high quality control, you can shield the honesty of your item and guarantee it meets your specifications.

The Facts About Premier Aluminum Llc Uncovered

This certain process can be automated and duplicated. Numerous elements that extremely made complex shapes can be manufactured using this procedure. Large quantities of components can be generated in just a brief duration of time. Prior to you begin searching for a dependable aluminum pass away wheel, there are some important things that you require to do.

You need to ask yourself what kind of aluminum pass away castings you need. After identifying what you need, you need to mention the specs of the light weight aluminum die spreadings you require. Figure out the weight, thickness, dimension, and various other specs of the aluminum die-cast you call for. It would additionally be better if you can attract and show all the dimensions of the aluminum die-cast.

After having this info, you can begin looking into aluminum die-casting makers. You can do this by just typing the keyword" Aluminum pass away casting producers" on the Google search engine.

Some of the questions you need to ask yourself are whether they have experienced and trained drivers, how much time their organization has actually been in procedure, or if they have some accomplishments. You can typically get the response to these questions from the supplier's web site. You can look into other sites or outside sources to confirm if the details provided on the supplier's website is authentic.

The Basic Principles Of Premier Aluminum Llc

One more thing you have to consider is the producer's ability to produce light weight aluminum die-casting items. To put it simply, the quantity of products the manufacturer can produce at an offered time. A few of the important questions you need to ask yourself are whether the producer can produce a higher volume or can the maker meet your demands.

(https://dzone.com/users/5257665/premieraluminum.html)What happens if your firm needs 10,000 items of particular device parts from the producer within one month? You purchased this quantity; nevertheless, the producer can only create 5000 items of these machine parts within one month (Aluminum Casting company). Therefore, you won't have the ability to receive the amount that you order promptly

Our Premier Aluminum Llc PDFs

It is crucial that you ought to ask if the manufacturer is implementing an in-house tooling procedure. Additionally, you need to ask the maker just how much the expense of in-house tooling is. The in-house tooling procedure, which permits you to create distinctive designs and shapes can be an additional price.

This element directly associates with the manufacturer's manufacturing ability. You have to search for a manufacturer that can guarantee quicker distribution of products. Nonetheless, this must be done in such a method that high-grade requirements are kept. This can ensure that you can obtain your products on schedule, and you can prevent missing out on those useful service chances.

This implies that there are several choices that you can select from. Today, customer needs continue transforming. It appears that clients are looking for an exceptional combination of top quality, cost-effectiveness, and durability. That is why it is greatly advised that click resources you must choose a producer that can generate different kinds of light weight aluminum die-cast products.

The Ultimate Guide To Premier Aluminum Llc

Usually, these light weight aluminum die-casting products will certainly need some designs, machining, or ending up touches. Having this in mind, you should search for a maker that can implement a variety of additional ending up works as soon as die casting is done. Some examples of completing procedures consist of Chromating, CNC Machining, Sandblasting, Powder covering, Anodized, E-coating, Damp paint, Plating, and much more.

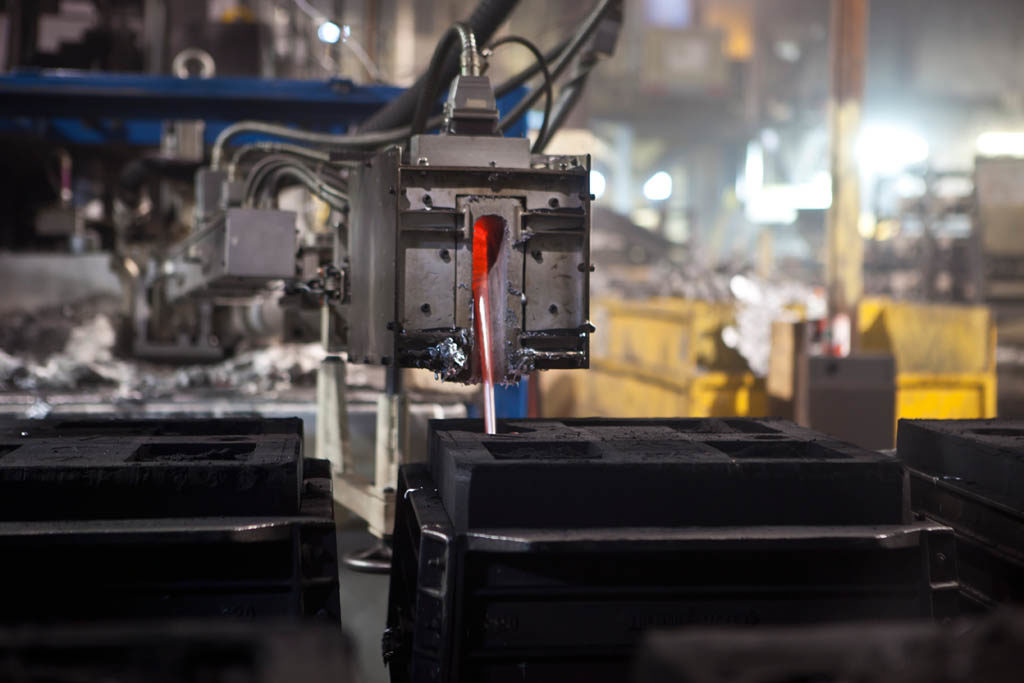

Die spreading is one of the most cost-efficient, precise, and protean production processes in the globe minute. The process includes fitting molten significance, under stress, right into a relevant die (earth), and previously strengthened it can be ejected and completed (if necessary) in a variety of means.